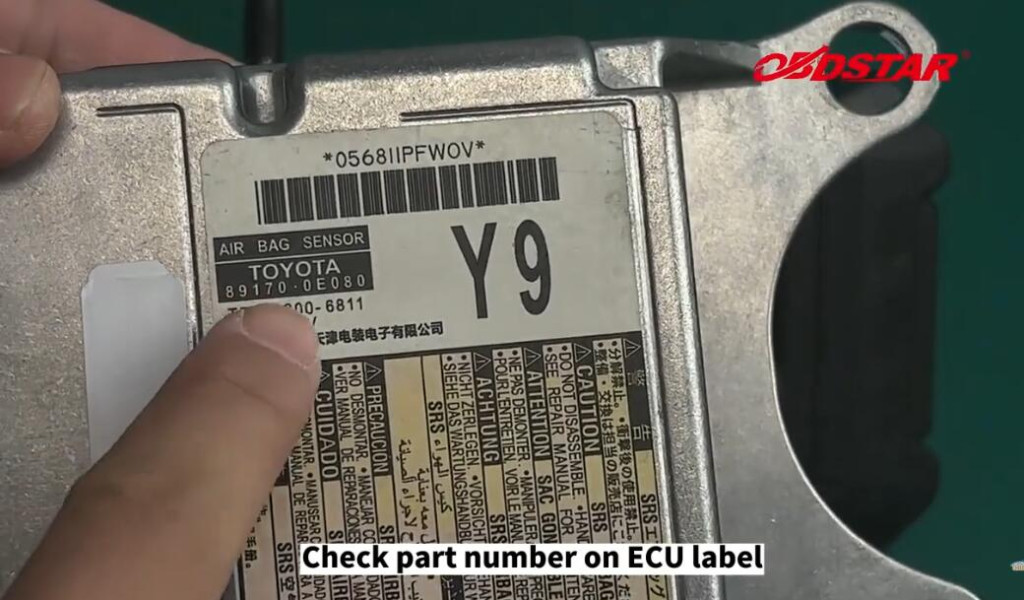

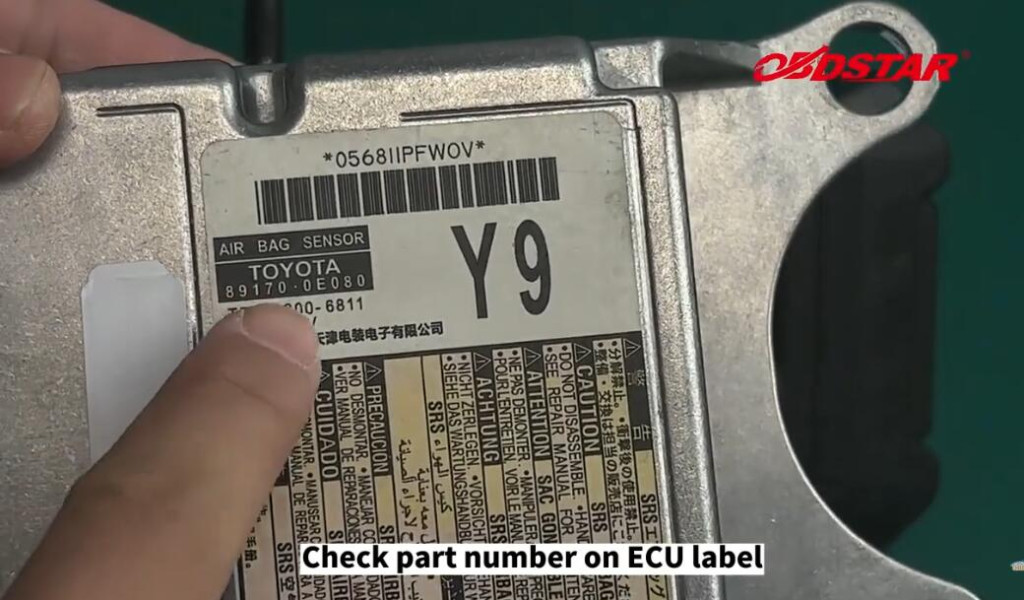

This is a tutorial on how to use OBDSTAR P50 Airbag Reset Tool on bench. Taking the Toyota 89170-0E080 airbag ECU as an example. Read this article to learn how it works.

Accessories Required

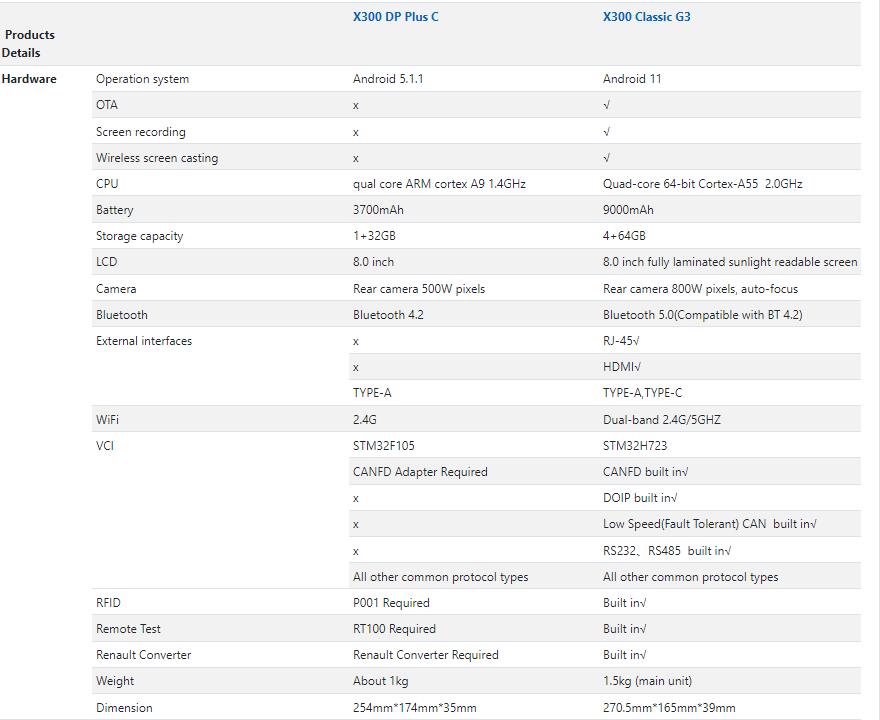

OBDSTAR P50

Toyota 89170-0E080 Airbag ECU

P004 Adapter

P004 Jumper

Main cable

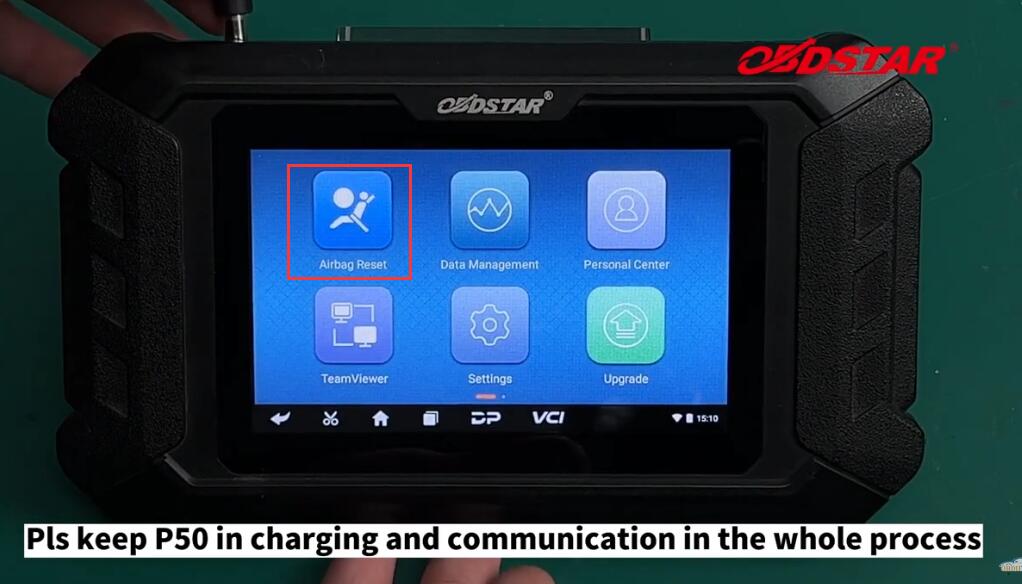

Note: Please keep OBDSTAR P50 in charging and communication throughout the whole process.

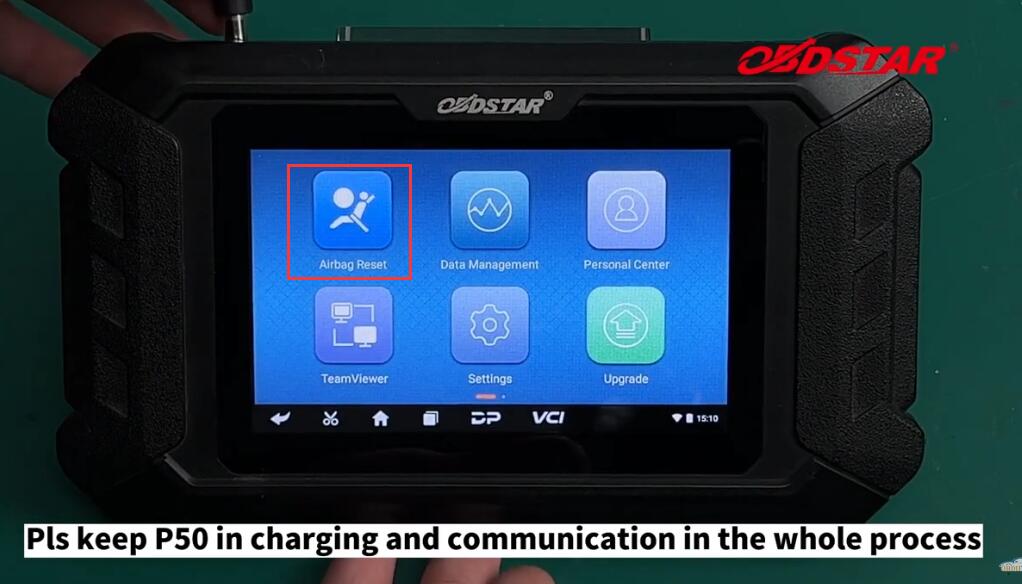

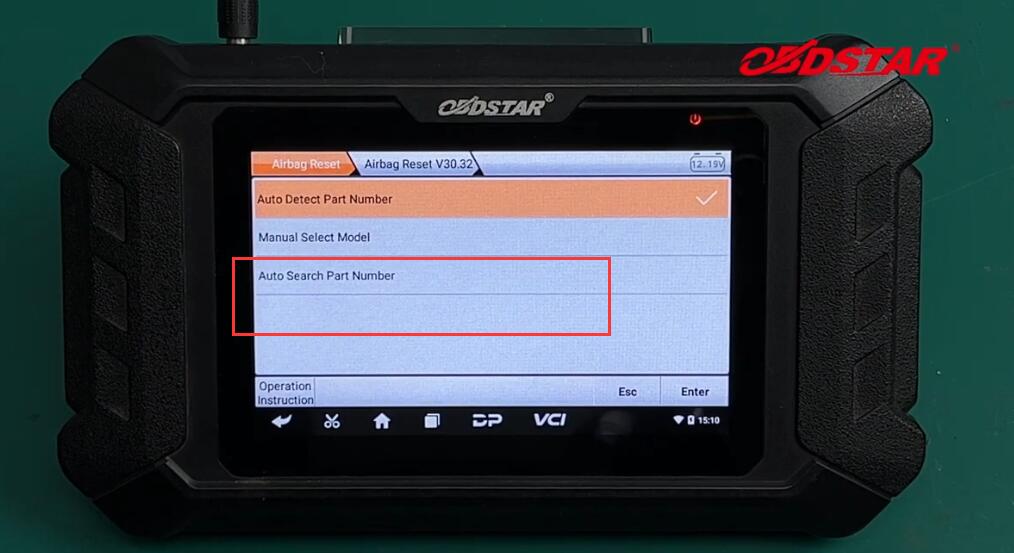

Airbag reset >> Latest version >> Auto Search part number

This function is available by connecting the server, please ensure the Internet connection is normal. Press “Enter”.

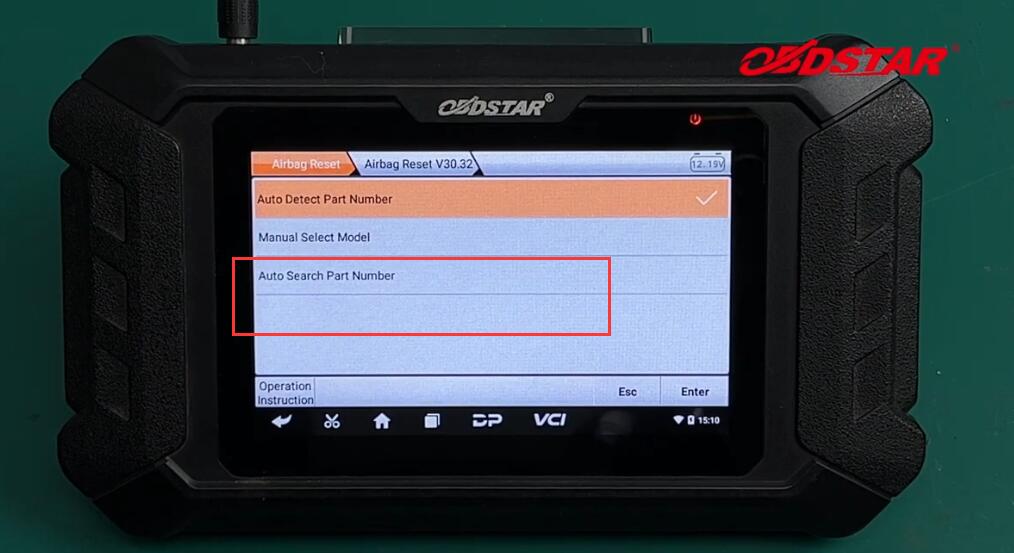

Check the part number on the ECU label to search for it.

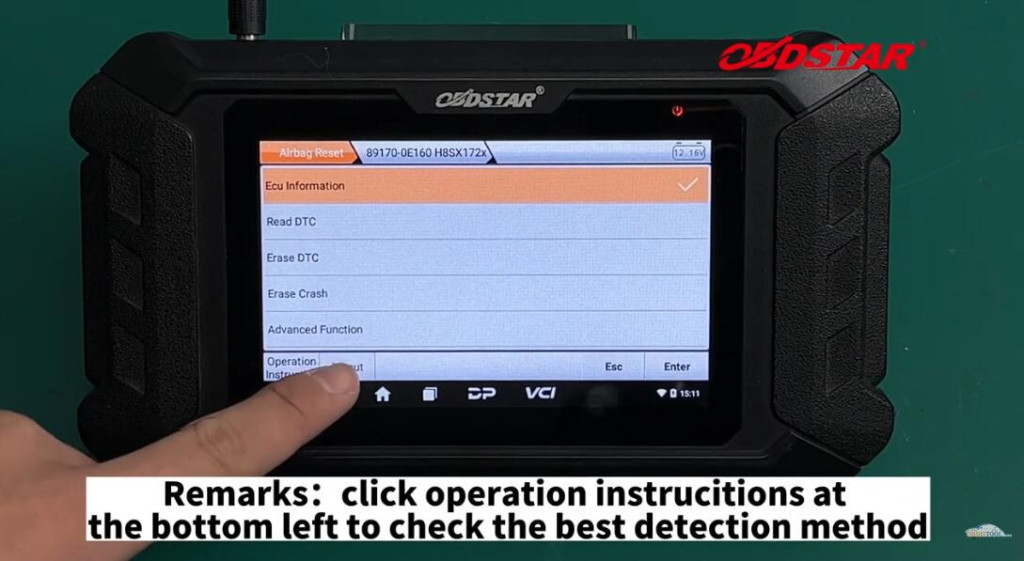

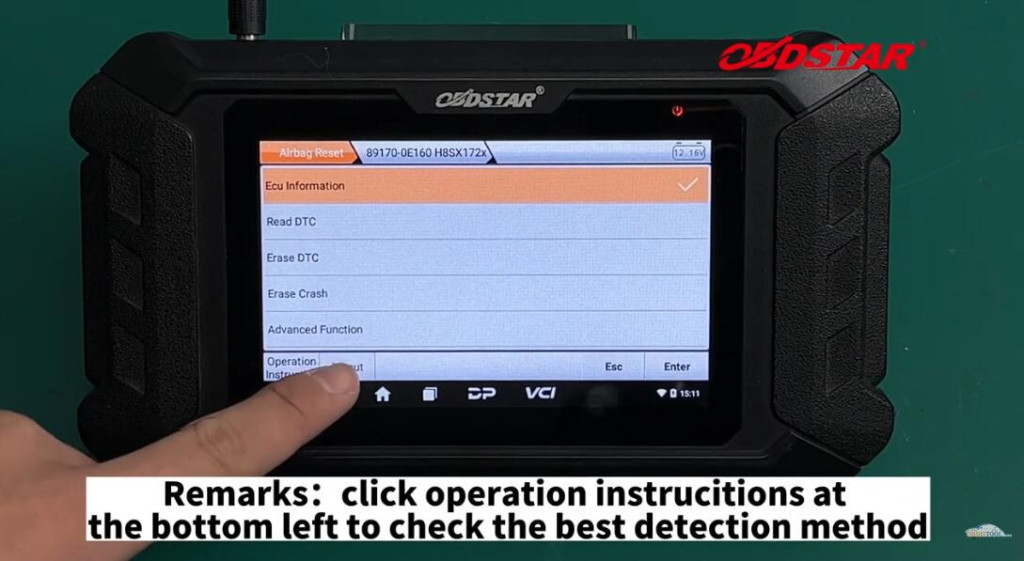

Note: before repairing the airbag computer, please carefully check “Operation Instructions” at the bottom left to check the best detection method.

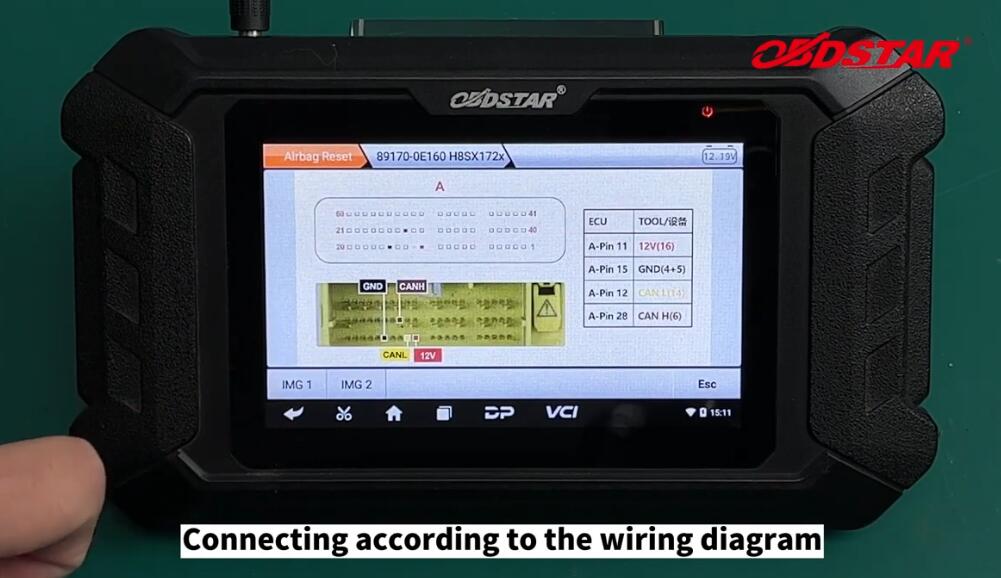

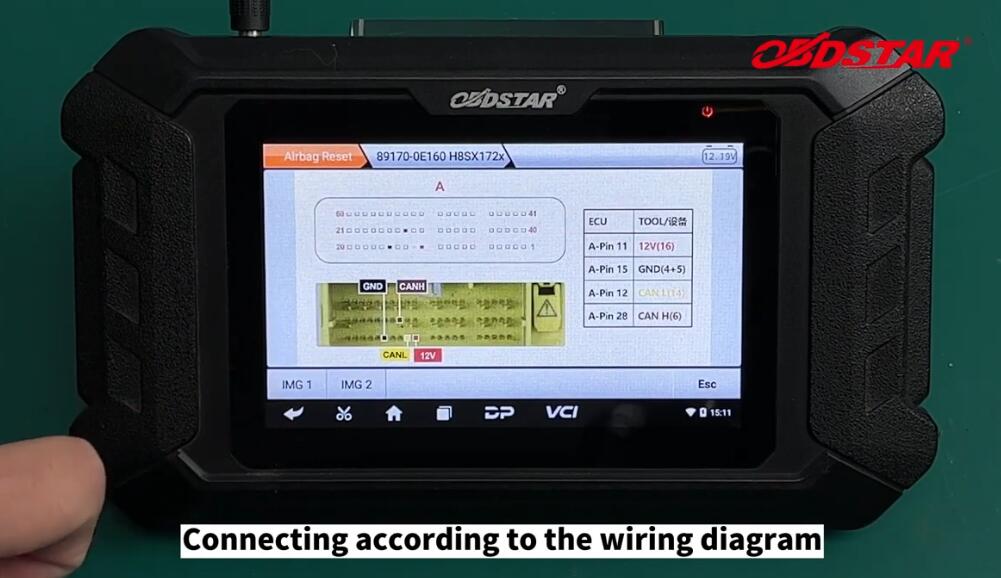

Connect according to the wiring diagram.

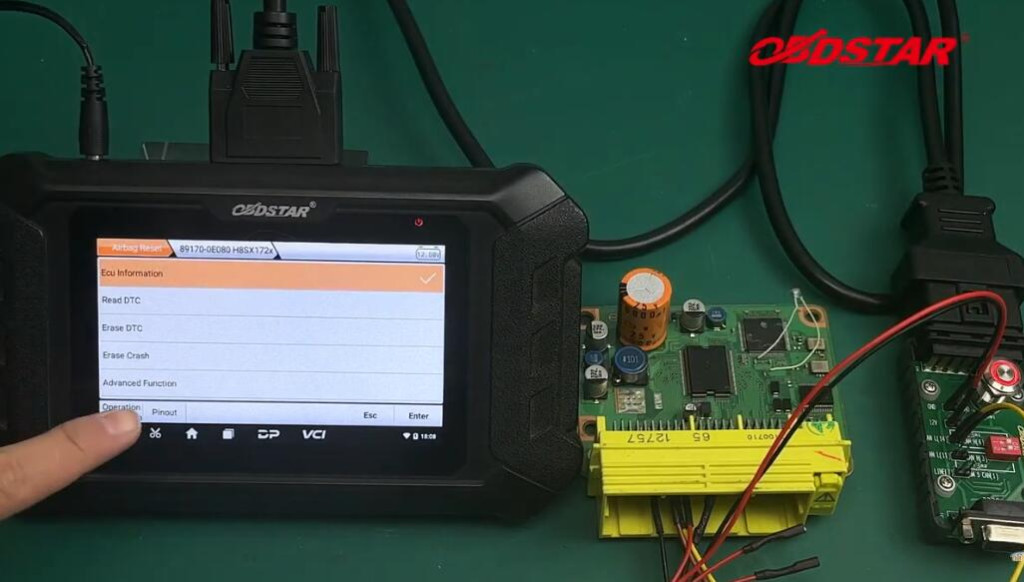

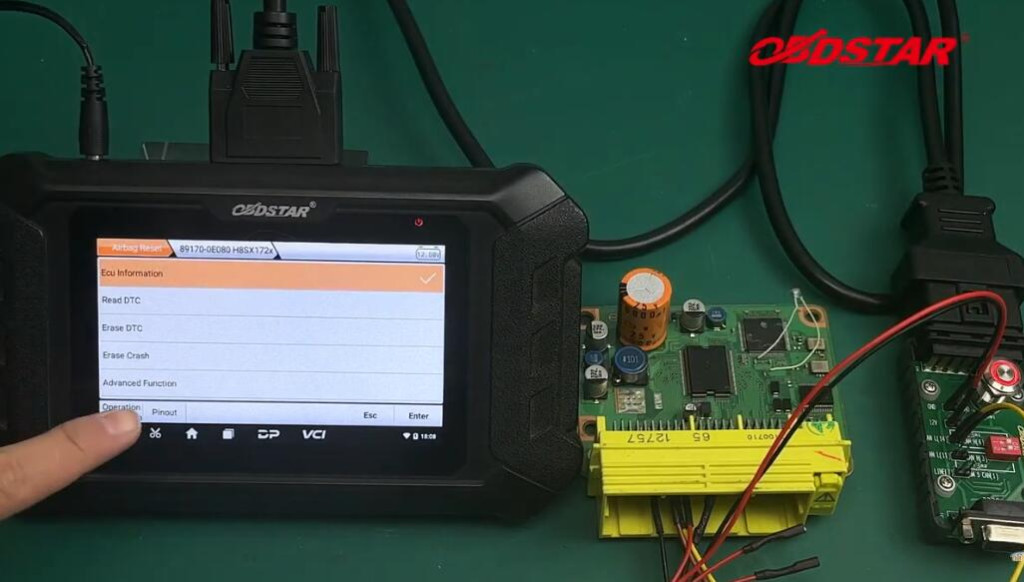

Turn on the P004 Adapter ignition switch to check ECU info.

We can see the “Crash Recorded” is YES.

Go to read DTC, there’s a crash fault.

Read FLASH(H8SX172x) >> Start

Save the data file.

Click “Erase Crash”.

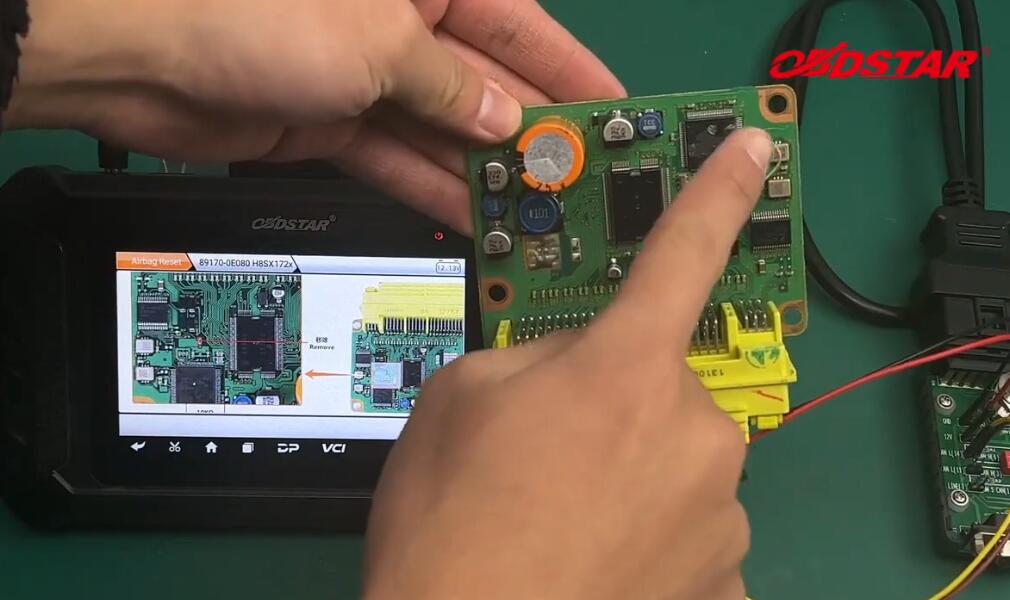

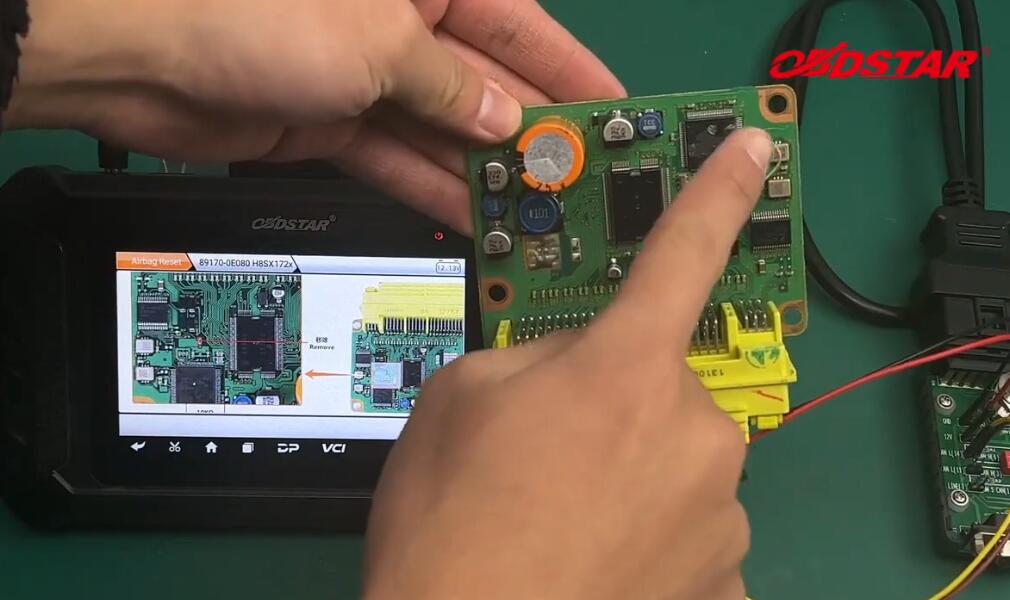

Executing the “Erase Crash” function will clear all flash data. Please ensure that the “Read FLASH” function has been executed. And open the cover to compare all write flash mode wiring diagrams in the “Operation Instructions”. There is a picture that can correspond to your ECU.

Otherwise, after executing this function, flash data can only be recovered through the programmer.

Enter >> Enter

Erase crash success. Please follow the wiring diagram of write flash mode, and execute the “Write FLASH” function after removing/welding the resistance.

Turn on the P004 Adapter ignition switch again.

Advanced function >> write FLASH(H8SX172x)

Confirm that the “Write FLASH” operation has been performed after removing/welding the resistance according to the write flash mode wiring diagram.

Enter >> Enter >> Selected data file >> Start

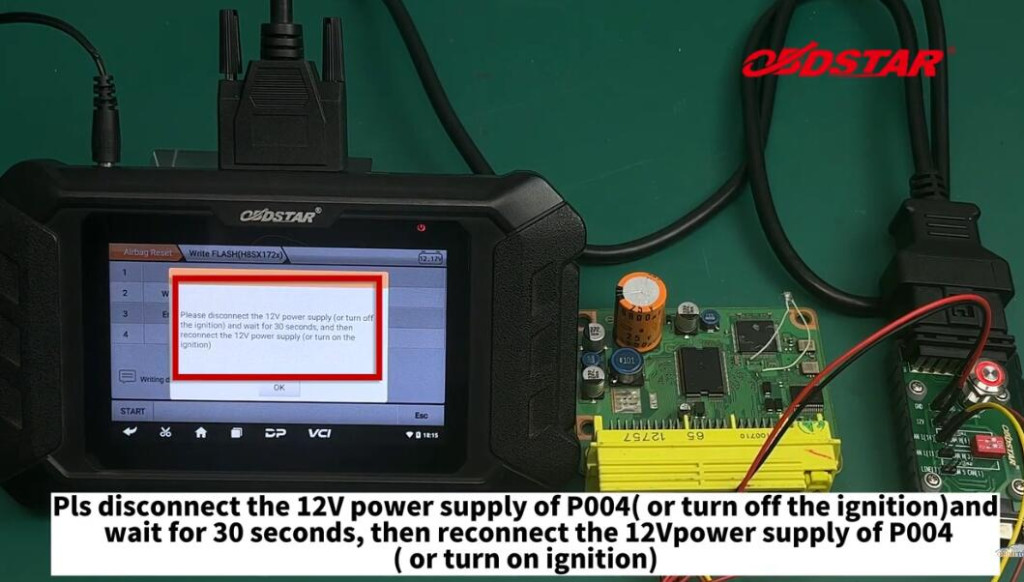

Writing data success.

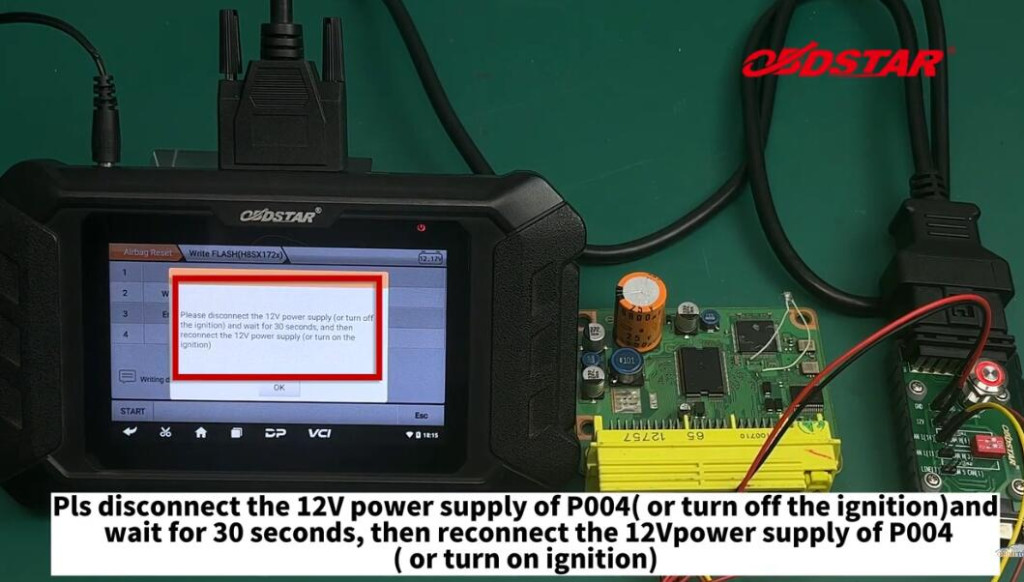

Please disconnect the 12V power supply of P004(or turn off the ignition) and wait for the 30s, then reconnect the 12V power supply of P004(or turn on the ignition).

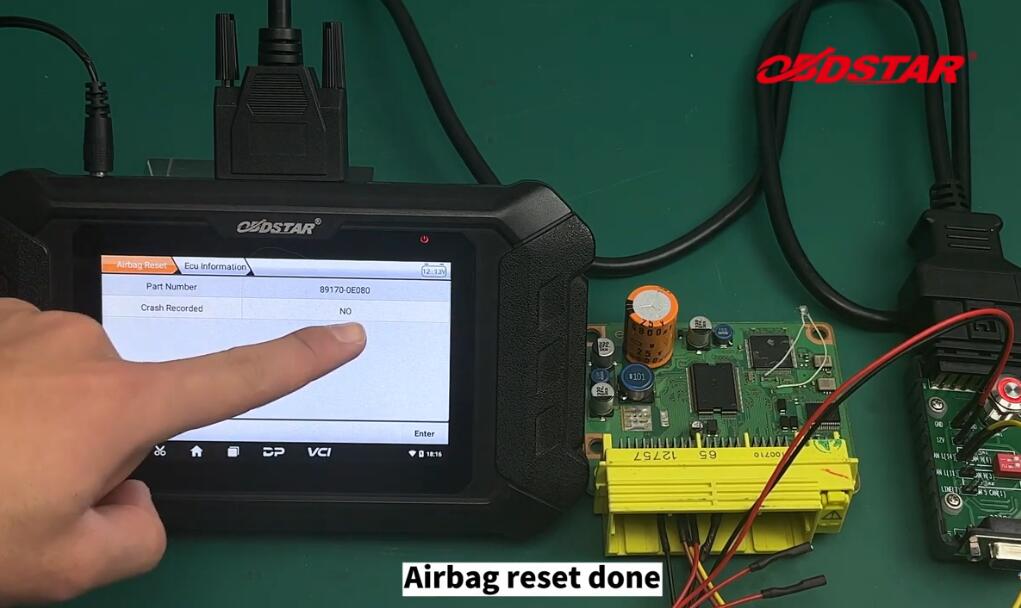

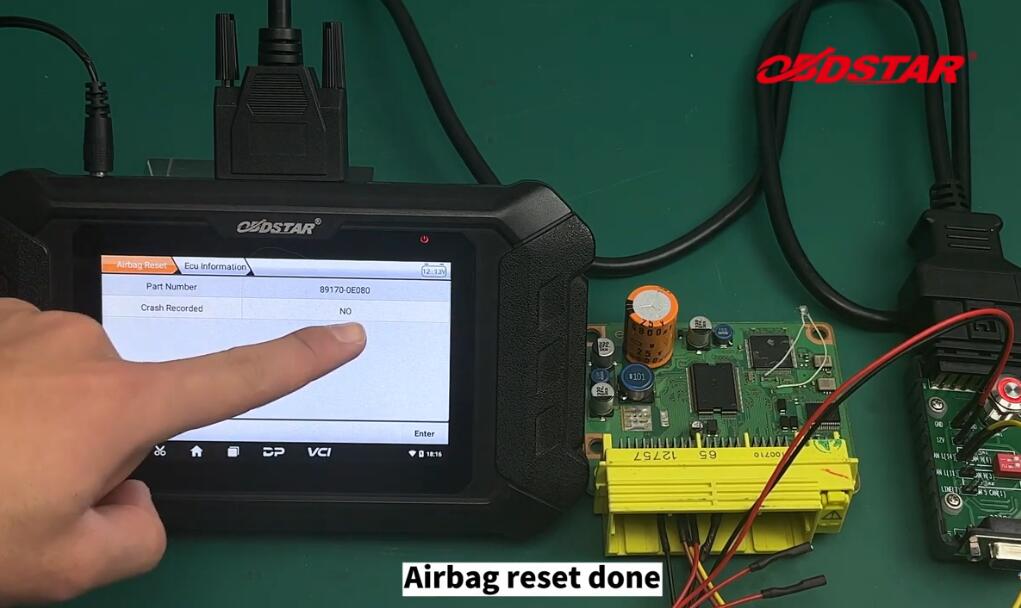

Go to erase DTC, then check ECU info again.

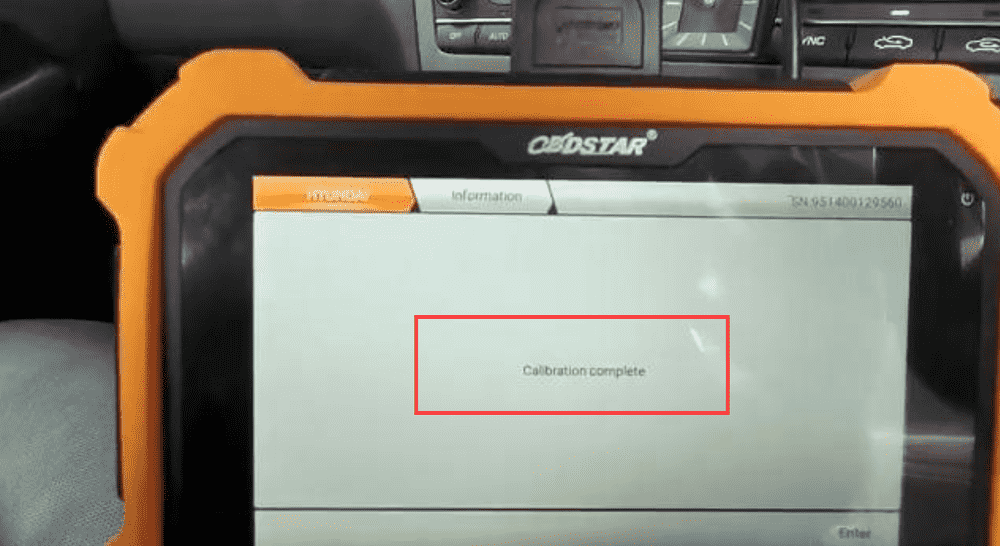

As we can see, the “Crash Recorded” has been changed to NO.

The crash fault has been cleared.

The airbag reset is done.